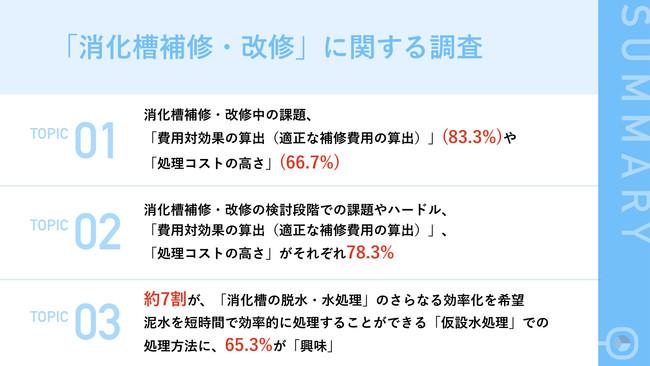

Issues during digestion tank repair/renovation, 83.3% of local government employees answered "cost-effectiveness calculation" Interested in "temporary water treatment" to improve the efficiency of dehydration and water treatment

~Survey of 101 local government employees on ``repair and repair of digestion tanks''~

Seisui Industry Co., Ltd. Seisui Industry Co., Ltd., which has the best temporary water treatment technology in Japan (Headquarters: Chiba City) Wakaba Ward, CEO: Kenichi Imoto, hereinafter referred to as Seisui Industry) conducted a survey on "digestion tank repair/renovation" targeting 101 people who work for local governments and have been managing digestion tanks in the past. I have done it and will post the results.Summary

Survey outline: Survey on ``repair/renovation of digester tank'' Survey method: Internet survey Survey period: December 14, 2021 to December 16, 2021 Valid responses: 101 people who work for local governments and manage digestion tanks " Q1.Are you currently performing or planning to repair or refurbish the digester?If there are more than one, please select all that apply.(Multiple answers)” (n=101). 22.8% answered that it is in progress, 20.8% answered that it was already completed, and 11.9% answered that it is currently being executed.Q1.Are you currently carrying out or planning to repair or refurbish the digester? If there is more than one, please select all that apply. (multiple answers)

・Currently under consideration: 22.8% ・Already completed: 20.8% ・Currently underway: 11.9% ・None in particular: 53.5% . Please look back on the completion and tell us about the issues after performing repairs and renovations. (multiple answers)” (n = 21), 47.6% answered “It cost more than expected”, 33.3% answered “It took longer than expected”, and “Unexpected problems occurred”. The answer was 19.0%.This is a question for those who answered "already completed" in Q2.Q1. Please look back on the completion and tell us about the issues after performing repairs and renovations. (multiple answers)

・It cost more than expected: 47.6% ・It took longer than expected: 33.3% ・An unexpected problem occurred: 19.0% ・Other: 0.0% ・Nothing in particular: 42.9% I would like to ask those who answered that they have completed it. If you have any questions other than those answered in Q2, please feel free to let me know. (n=21), we received 8 responses, such as "It would be helpful if the cost was a little lower" and "It was a large-scale construction, so I was afraid of the impact on the building."

This is a question for those who answered "Currently running" in Q4.Q1. Please let me know the issue at runtime. (multiple answers)

・Cost-effectiveness calculation (appropriate repair cost calculation): 83.3% ・High processing cost: 66.7% ・Appropriate processing method: 50.0% ・Ensuring safety of management: 50.0% ・Securing management personnel: 25.0%・Others: 0.0%・None in particular: 0.0% "I would like to ask those who answered 'currently in progress' in Q5.Q1. Please feel free to let me know if there are any issues during execution other than those answered in Q4. (n=12), we were able to get 9 answers, such as "Will the delivery date be as planned due to parts shortages?"This is a question for those who answered "already completed" or "currently running" in Q6.Q1. What is the purpose of the repair/renovation work? (multiple answers)

・Corrosion prevention: 73.3% ・Earthquake resistance: 56.7% ・Change to facilities for power generation: 33.3% ・Processing due to consolidation of sewage treatment plants: 33.3% ・Others: 6.7% "Currently under consideration" in Q7.Q1 I would like to ask those who answered Please tell us about the challenges and hurdles in doing it. (multiple answers)” (n = 23), 78.3% answered “high processing cost”, 78.3% answered “calculation of cost-effectiveness (calculation of appropriate repair cost)”, and 78.3% answered “safety of management”. Securing” was the answer of 56.5%.This question is for those who answered "currently under consideration" in Q7.Q1. Please tell us about the challenges and hurdles in doing it. (multiple answers)

・High processing cost: 78.3% ・Cost-effectiveness calculation (appropriate repair cost calculation): 78.3% ・Ensuring management safety: 56.5% ・Appropriate treatment method: 52.2% ・Securing management personnel: 8.7%・Others: 0.0%・Nothing in particular: 0.0% When asked "Q8. Do you want to improve the efficiency of dehydration and water treatment in the digester in the future?" 33.6% answered, and 33.7% answered “somewhat”.Q8.In the future, would you like to improve the efficiency of dehydration and water treatment in the digester?

・I strongly agree: 33.6% ・Slightly agree: 33.7% ・Somewhat disagree: 19.8% ・I don't agree at all: 12.9% ``I would like to ask those who answered 'I agree very much' or 'I agree somewhat' in Q9 and Q8. What do you think is necessary to make dehydration and water treatment more efficient? (multiple answers)" (n = 68), 57.4% answered "overall processing design tailored to the site", 50.0% answered "countermeasures and preparations for trouble", and "equipment and systems that can smoothly sort materials". The answer was 45.6%.This is a question for those who answered "I agree" or "I agree somewhat" in Q9 and Q8. What do you think is necessary to make dehydration and water treatment more efficient? (multiple answers)

・Overall processing design tailored to the site: 57.4% ・Troubleshooting/preparation: 50.0% ・Equipment and system that can be sorted smoothly: 45.6% ・Building detailed mechanisms according to the situation: 39.7% ・Team that executes processing construction: 25.0%・I don't know: 2.9%・Others: 1.5% "Q10. Would you be interested in a "temporary water treatment" treatment method that could efficiently treat muddy water in a short time? ”(n=101), 18.8% answered “very interested” and 46.5% answered “somewhat interested”.Q10.If there is a treatment method for "temporary water treatment" that can treat muddy water efficiently in a short time, would you be interested?

・Very interested: 18.8% ・Somewhat interested: 46.5% ・Not very interested: 19.8% ・Not interested at all: 14.9% This time, I worked for a local government and managed digestion tanks/Past We conducted a survey on ``repair/renovation of the digester tank'' for 101 people who had First, when asked about "repair/renovation of the digester", it was found that 22.8% were "under consideration", 11.9% were "in progress", and 20.8% were "completed". As for the purpose of repair/renovation work, 73.3% cited "corrosion prevention", and about half of them cited "cost was higher than expected" as an issue after performing repair/renovation work. Specifically, there are episodes such as ``I was afraid of the impact on the building because it was a large-scale construction''. In addition, as issues during digestion tank repair/renovation, "Cost-effectiveness calculation (appropriate repair cost calculation)" (83.3%) and "High processing cost" (66.7%) were cited, and "Parts There were also concerns about whether the delivery date would be as planned due to shortages, etc. Next, when asked about issues and hurdles at the stage of examining digestion tank repair/refurbishment, "calculation of cost-effectiveness (calculation of appropriate repair costs)" and "high processing cost" were the highest at 78.3% each. have become. It can be read that there are issues related to "cost" in all processes, such as the examination stage, execution stage, and completion stage. Approximately 70% of respondents hoped for further efficiency improvements in the dehydration and water treatment of digestion tanks in the future, and approximately 60% believed that an "overall treatment design tailored to the site" would be necessary to achieve this. I understand. Finally, 65.3% expressed interest in the treatment method of "temporary water treatment," which can effectively treat muddy water in a short time. In general, digestion tank repair and renovation work requires a large amount of money, but with the "temporary water treatment" treatment method, it is possible to handle only the necessary repairs at the optimum cost. In addition to being time-saving and cost-saving, it is also an environmentally friendly solution, so it is likely to attract more and more attention in the future.For digestion tank | Temporary sludge volume reduction plant

A temporary sludge volume reduction plant is used when the digestion tank is demolished, equipment such as agitators in the tank is renewed, or when the sludge in the digestion tank needs to be dredged for repairs, etc. It is an alternative method to URL: https://seisui-kk.com/service/plant/syoukasousyunsetu/ Company name: Seisui Industry Co., Ltd. Established: December 1974 Representative Director: Kenichi Imoto Location: 424-18 Kamiizumi-cho, Wakaba-ku, Chiba-shi, Chiba Business content within the research park: ・IHI Business Partner Co., Ltd. (sales of decanter-type centrifuges) ・Water treatment equipment when renewing water treatment equipment ・Plant rental ・Emergency response in the event of trouble with water treatment equipment ・By renting water treatment equipment Industrial waste volume, industrial waste cost reduction, centrifuge rental/sales (new products, resale machines) URL: https://seisui-kk.com *The following is special information limited to media personnel. Please refrain from disclosing information on personal SNS etc.This press release contains information for members of the media.

If you register as a media user, you can view various special information such as contact information for company representatives and information on events and press conferences. *The content varies depending on the press release.