Introducing the forefront of the equipment manufacturers that find business opportunities in the microscope of semiconductors

Hitachi High -Tech's electronic line wide view field test system "GS1000"

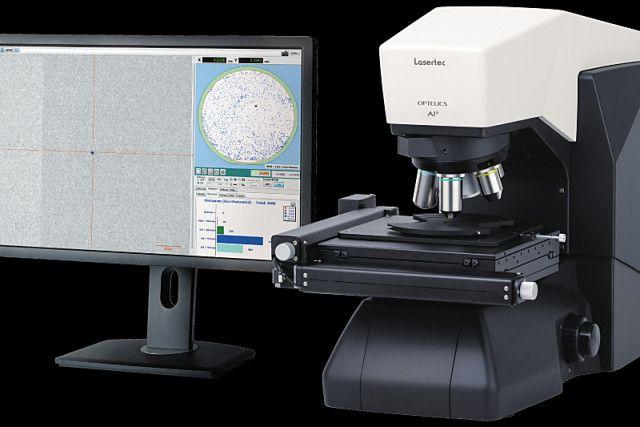

The semiconductor industry that grows remarkably on the backdrop of the spread of 5th -generation communication (5G) and the progress of IoT (Internet of Things). Manufacturer manufacturers have found business opportunities for needs such as miniaturization of semiconductor circuits and improving productivity. He followed the forefront at the semiconductor international exhibition "Semicon Japan 2021 Hybrid". [Photo] The device that cuts silicon wafers in the world's leader, Hitachi High -Tech, exhibited the GS1000, an electronic line wide viewpoint test system that can be stable and accurately inspected and measured the fine circuit pattern of the semiconductor. The device is equipped with a aberration correction device developed by the state -of -the -art electronic optical design. In general, if you try to measure in a wide -visible field, the resolution around the measured object will decrease. The device can be inspected and measured at a high precision even in the extensive region. A high -precision image with 100 times the width scanning of the circuit width, which is one of the main products of the company, is a measuring device of the circuit line width. While the introduction of the EUV (extreme ultraviolet rays) exposure process is expected to expand due to the growing demand for microscopic demand, the EUV has a task such as a circuit range variation more likely to occur compared to the conventional exposure method. The need for inspection measurements for high -speed, high sensitivity, and extensive regions is increasing. The advanced test introduced the industry's fastest image processing engine "T2000 IP Engine 4" for test (test) of a supplementary metal oxide semiconductor (CMOS) image sensor. The speed of image processing is improved by about 10 times compared to the conventional. Contributes to shortening test time and cost reduction.

The engine is compatible with the company's test device (tester) T2000. "Heterogenius computing", which performs calculation processing using different multiple processors, has been adopted. The defect of the output data of the CMOS image sensor of the cutting -edge high resolution can be detected at high speed. The CMOS image sensor is used in smartphone cameras. As the test time is longer due to the high pixel of the sensor, the need to test at high speed is growing. On the other hand, the world -leading disco in the semiconductor wafer cut, grinding, and polishing devices exhibited conventional products instead of new products. If a newly developed device is released and exhibited, it will take time to respond to mass production of the device. In order to make the most of the management resources, we did not exhibit new products. With the global semiconductor shortage of semiconductors, the company rushes to increase full pitch production against strong demand from customers. As a manufacturer manufacturer, it will be the priority of supply priority.

Nikkan Kogyo Shimbun, Kyoko Hariya