Wind and flood damage recovery is key to initial speed Top-notch instructors teach practical how-tos

Kimura: There are two changes in recent flood damage. One is deeply submerged. Heavy rain in western Japan was typical. There are more cases where the middle of the second floor of the building is submerged in water.

The other is that, like last year's Typhoon No. 19, a very wide area from Kanto to Tohoku will be uniformly damaged. Due to the severity of the damage and the spread of the disaster, it is taking a long time to recover. Looking at Mabi Town, Okayama Prefecture, where most of the city was flooded two years ago, and Joso City, Ibaraki Prefecture, in 2015, it is not uncommon for flooded areas to take six months to a year or more to recover.

Banya Our company provides disaster recovery services for companies, but we are aware of the increasing severity and spread of flood damage. It is said that due to the effects of global warming, typhoons have grown in size, and a large amount of rain has come to fall over a wide area. After the torrential rains in western Japan two years ago, we supported more than 50 restoration projects, mainly at factories in the Chugoku region, and in the Toyono area of Nagano City, Nagano Prefecture, where the flooding of Shinkansen bullet trains was widely reported during last year's Typhoon No. 19, and the Tohoku region. bottom. Dr. Kimura, you also conducted a detailed survey of the situation in the affected areas during the torrential rains in western Japan.

Kimura: My research targets in the affected areas are mainly ordinary houses, but I have seen many cases where delays in the initial response lead to more damage to houses. In the event of flooding, quickly dispose of water-damaged tatami mats, furniture, and electrical appliances, remove water and mud from under the floor, cut off wet gypsum boards and insulation, and then blow the building under the floor for at least one month. Let it dry slowly by sending it.

But the first aid doesn't go smoothly. I often hear that many residents have no experience with floods and do not know what to do. There is a shortage of volunteers, and the number of local builders is also decreasing. It is not uncommon for the builders that built them to have already gone bankrupt. In addition, due to the diversification of construction methods and construction materials, it is difficult even for the contractor who built the house to provide an accurate first aid. The number of prefabricated houses is increasing, but many of them are assembled in one piece at a factory and are not designed for repair. The slower the response, the greater the secondary damage, such as the growth of mold and the corrosion of building structural members such as columns and braces. Getting started quickly isn't easy.

Banya: I see, what you just said is the same for the recovery of companies and factories. A quick start remains important. In our case, especially in the case of natural disasters such as floods, we do our best to arrive at the affected area as soon as possible and to be there within a few hours of being contacted. Buildings can also be washed immediately and forced to dry to prevent the growth of mold and other health hazards. Also, in the case of factories, production equipment is often submerged as well, and one factory in the Chugoku region said, "The most troublesome thing is that support does not come immediately." . Even when he asked for help from equipment manufacturers, they were all told that they would not be able to help him until several months later. In that respect, our turn will come, as we can restore a wide variety of machines and facilities regardless of the industry.

Prompt recovery of even one-of-a-kind items with proprietary technology

-Professor Kimura pointed out that a quick initial response is essential in order to minimize mold and corrosion in general housing. What is the importance of the initial response in industrial machinery and equipment?

Kanzan: After all, it is a measure against corrosion. Flood restoration is a battle against corrosion, mainly rust progression. It is no exaggeration to say that the key is the initial action. Therefore, washing and drying should be carried out as soon as possible. Use a high-pressure washer to quickly wash away dirt such as mud.

However, our cleaning does not end there. In order to determine the state of contamination, the impurities adhering to the metal surface and pH are examined. If the result of the investigation is acidic, it is neutralized with an alkaline detergent, and if it is alkaline, it is neutralized with an acidic detergent. After that, rinse with low-conductivity DI water (water with a low inorganic salt content close to pure water). Washing with tap water alone is dangerous. Because it contains inorganic salts and chlorine, it can cause rust.

We use more than 40 unique drugs developed at our headquarters in Germany. Even if a precision electronic device equipped with an electronic circuit board, such as a server, is submerged in water, it can be restored using a high level of precision cleaning technology.

Banya When we say drying, what we are doing is not natural drying using fans or air blowers, but rather forced drying, where the object is sealed and the humidity is forcibly removed and released outside. is.

In the case of machines, we also individually package them to block the outside air and run a dehumidifying dryer to remove moisture. The method of forced drying varies according to the structure of the building and the material of the machine, and our manual covers 80 pages.

In the case of precision electronic equipment, we use a vacuum drying method that does not damage the electronic substrate. By lowering the atmospheric pressure, the boiling point is lowered, and by using the property that water evaporates at a lower temperature, delicate parts can be dried safely and reliably.

Kanzan: Depending on the conditions, rust progresses faster, and there are many cases where rust has already occurred upon arrival. However, our disassembly and cleaning technology enables restoration, including rust removal. Metal machinery that had been submerged in seawater for two weeks due to high tides caused by heavy rains in western Japan and had rusted to a considerable extent was restored without any problems. In addition to using our own chemicals properly, we use special techniques such as ultrasonic cleaning for finely disassembled parts to remove rust.

Kimura: Since there is no flood recovery know-how in the affected areas, there are cases where people continue to live there thinking that they will be fine just by cleaning the visible area, and the damage will spread later. Because it doesn't know hidden "wetness" such as insulation behind walls. Even if you were relieved with a small amount of flooding above the floor, damage such as a dent in the floor later occurred.

Banya: You are exactly right. It's not uncommon for us to receive consultations even after two months have passed since the disaster. I did some emergency measures on my own, but after a while, there was a strange smell, and when I opened the inside, there was a case where mold had grown.

Kanzan You can't let your guard down even with light flooding. Even at companies, I see employees washing machines and drying them with blowers, thinking they can restore them on their own. However, in reality, simply circulating air will not reduce the humidity, and even if you work hard, it will not lead to drying and rust will progress.

In the case of machines, we dismantle them and check even the smallest parts to remove dirt and rust. There have been cases where requests have been made to our company, and as a result, the time it takes to resume operations has been extended.

Kimura: It is reassuring to be able to recover a machine that has been submerged in water by disassembling and cleaning it. In Japan, there are places that use old one-of-a-kind machines that cannot be replaced. The 7.13 torrential rain that occurred in Niigata Prefecture in 2004 flooded a nearly 100-year-old loom at a textile factory. The unique texture cannot be produced without the machine, but it was no longer possible to replace it. When I was in trouble, a client company that had experience with the 2000 Tokai floods immediately rushed over and helped me with the recovery work, and showed me the machine. I learned that if a flooded machine can be repaired as soon as possible, it can be used again, that know-how based on experience is essential, and that early recovery will enable business continuity.

Banya: I understand very well. In Japan, the same machines are used for a long time with proper maintenance, and there are many pieces of equipment that are one-of-a-kind. Also, after 10 or 20 years, some products may be discontinued or the manufacturer itself may go out of business. Even if you replace it with new equipment, there may be some fibers that cannot reproduce subtle differences such as texture. If there are a lot of equipment in front and behind, it may be difficult to pinpoint replace only that part due to differences in takt time. Our disaster recovery basically restores existing equipment to the state it was in before the disaster, thus avoiding such problems and saving a lot of money and time.

Specialists at the level of advanced countries dealing with flood damage

--Is there a way to make up for the lack of know-how and human resources for flood damage restoration?

Kimura: The importance of drying is well known, but the other is to learn from other countries. For example, the United States is one of the countries with advanced flood control measures. There are public recovery manuals for flood damage. It contains instructions on how to do it safely and without harming your health.

Concrete measures such as paying attention to electricity and gas in disaster areas, wearing masks, wearing equipment such as shoes suitable for work, washing hands after work, and avoiding work for those with underlying diseases such as allergies and asthma. A workaround is indicated. Japan is very weak in this regard. This is a point to learn from.

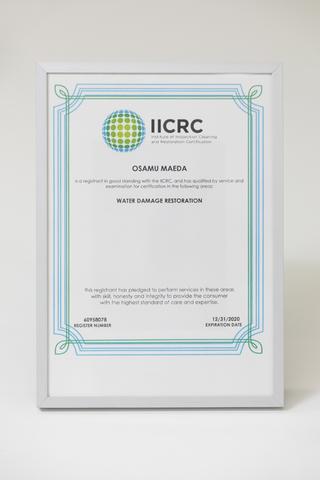

Banya: It's true that in Europe and the United States, manuals are more advanced than in Japan. We also invite trainers from the Institute of Inspection Cleaning and Restoration Certification (IICRC) in the United States to conduct training on restoration methods after flood damage. A company with nearly 50 years of history in standardization and technical certification of cleaning and restoration technology.

Maeda I am one of the IICRC's certified flood restoration engineers. My impression is that the training is thorough, from studying the basics of science to acquiring the perspectives that are essential for on-site work.

For example, regarding drying, you will learn about the relationship between indoor and outdoor humidity and temperature, the effective installation location of fans, and how to derive the required number of installations. You will also learn how to deal with dangers encountered in the field, such as how to secure safe entrances in disaster areas and how to install electrical wiring.

Also, it is easy to think that it is rudimentary, including training on the correct use of protective clothing and masks, but high consideration is given to safety. The content was logical, so it was very useful for me to acquire efficient initial work and the ability to detect crises. Equipment and on-site confirmation points are organized in a checklist format to prevent mistakes.

Kimura: That's wonderful. Checklists are really helpful. Volunteers in Japan are getting better, but they still have to go ahead and learn from other countries.

Manuals for disaster volunteers in Japan have also been improved, but there is still a strong awareness that flood damage = mud, and it says that you should wear rubber boots and rubber gloves. However, when a part of a member is removed as an emergency measure, nails may stick out here and there, or nails may be stuck in the removed member. If you don't have safety shoes or at least safety insoles in your shoes, you'll step through your nails. Also, if you don't use reinforced gloves such as leather gloves, your hands will get stuck. Once it pierces the body, it can cause tetanus. Even if it is a flood, safety preparations will change depending on whether it is mud removal or emergency restoration. The reality is that the awareness of safety and the viewpoint of protecting one's body are still weak. It is often seen that disaster victims do not know such manuals and work without thinking that it is dangerous.

The meaning of disinfection is also not understood. It is a big problem that is not understood not only by citizens but also at the administrative level. Kurashiki City proactively distributed slaked lime for disinfection during heavy rains in western Japan. However, there were many local people with poor eyesight, and after a week, the city called on people to stop using slaked lime. The CDC (Centers for Disease Control and Prevention), which governs public health in the United States, points out that slaked lime does not have a disinfecting effect and is harmful if it floats into the eyes or is inhaled.

In this way, it is important to carry out restoration work safely and appropriately based on correct knowledge in wind and flood disaster countermeasures.

Short-term, low-cost recovery is the key to business continuity for affected companies

-What is the outlook for future flood control?

Kimura: On a national level, the increase in storm and flood damage will increase the amount of insurance payments. According to the announcement by the General Insurance Association of Japan, insurance premiums paid for the heavy rains in July 2018 amounted to approximately 200 billion yen, and Typhoon Hagibis in 2019 reached approximately 550 billion yen.

2018 was the first time that the non-life insurance industry in Japan paid more than 1 trillion yen for wind and flood damage. In 2019, wind and flood damage alone is expected to exceed 1 trillion yen, exceeding 1 trillion yen for the second consecutive year. Insurance premiums will naturally rise, and the stability of the insurance system may be shaken.

In small and medium-sized enterprises, large subsidies such as group subsidies have been established since the Great East Japan Earthquake in the event of a major disaster. 50% to 70% will be subsidized for replacement of equipment, but the rest will be self-funded. In addition, if the scale of the disaster is large, it will take time from application for subsidy to adoption, purchase of equipment, installation, and operation. During that time, there will be no revenue and, in some cases, the market will be lost to other companies. In addition, recovery with subsidies tends to result in excessive capital investment. It is not uncommon for companies to go bankrupt after 5 or 10 years due to lower than expected sales.

From these two points of view, I think it is reasonable to request recovery from a professional company with high technical capabilities such as RecoveryPro, which can keep costs down in a short period of time, rather than an expensive replacement. In the future, we expect to enter the service for general housing.

Banya: Thank you. We also have business alliances with several major non-life insurance companies, and I feel that the role we play in the insurance system is increasing as the number of natural disasters increases. We would like to rush to the customer's difficulties as soon as possible and support them with short-term and low-cost recovery. RecoveryPro is celebrating its 10th anniversary this year. We will continue to strive to further improve our technical capabilities and strengthen our system.